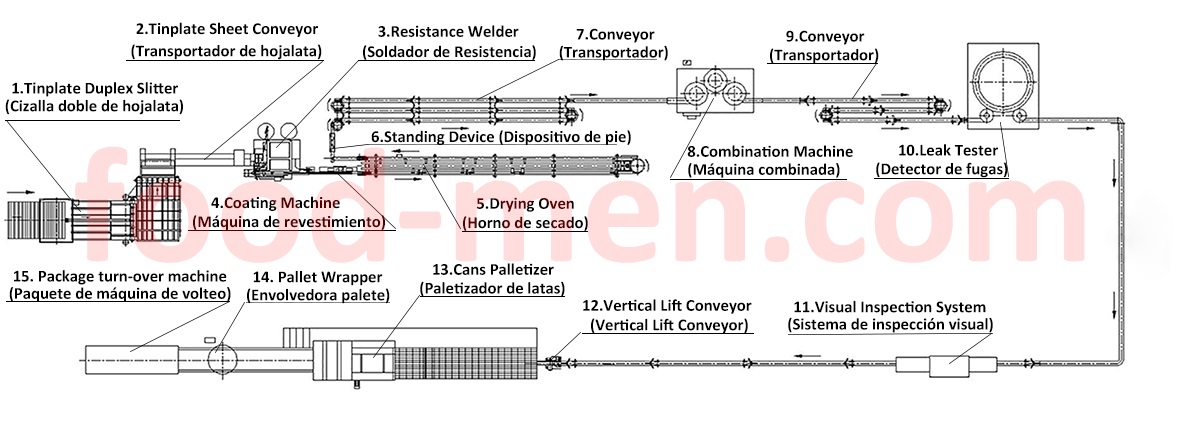

3-piece Big Can Body Making Machines Line

Item No.: MLF-G3-2016

This 3-piece big can body making machines line is highly automated machinery, the machines can complete the making of high-quality 3-piece big can body for food.

| Product parameters |

| Product Name: |

3-piece Big Can Body Making Machines Line |

| Model Number: |

LF-G3 |

| Brand: |

SHANQING |

| Minimum Order Quantity: |

Part of the 3-piece big can body making machines line can be ordered. |

| Price: |

The price is determined according to the parameters and quantity of the order. |

| Supply Ability: |

1 three-piece big can body making machines line per month |

| Place of Origin: |

China |

INQUIRY