Method of Drinking Water Automatic Treatment and Purification

Published date and time: 2020-03-21, 15:20

Date and time of modification: 2021-05-02, 16:58

Author: Food-Men

This article introduces the Method and principle of drinking tap water automatic treatment and purification. It can automatically treat (purify) raw water from rivers and mountains into drinking water.

The water in rivers and lakes is surface water. Generally, the water is turbid, the microbial content is large, and it is easily polluted by the environment. For some areas with good natural environment, its rivers and lakes are not polluted seriously. Using this automatic drinking water treatment method will save water treatment costs. Of course, the waters are polluted serious, measures such as activated carbon filtration and inverting osmosis need to be added.

The mountain water and well water are groundwater. They are generally clear and transparent, and have low microbial content. Most of them are raw water that is not suitable for human drinking. The salinity and total hardness of water are high. In some areas, groundwater has higher levels of iron and manganese, while some have more calcium carbonate. Groundwater usually has a low water season and a high water period. During these two periods, the quality of water will change. In addition, as the industrial process continues to accelerate, the pollution of the environment is becoming more serious, and groundwater is inevitably polluted. Therefore, we must regularly check the quality of water and take reasonable water treatment measures.

Whether it is raw water of rivers, lakes, mountains or wells, the quality of water should be checked regularly in accordance with the "standard for drinking water". Use water treatment purification measures accordingly.

Drinking Tap Water Automatic Treatment and Purification Process

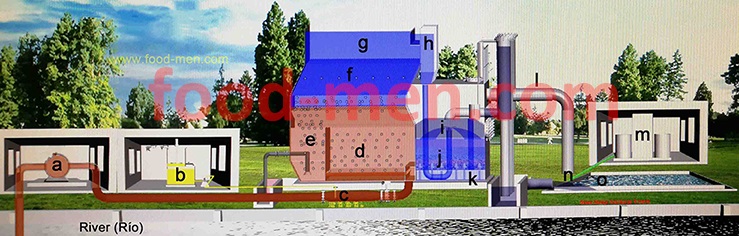

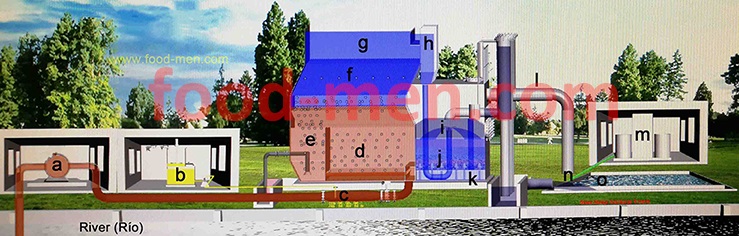

Drinking tap water automatic treatment and purification process is shown in the following figure:

•The water is transported from the raw water pump (a) to the pipeline mixer (c);

•The water is transported from the raw water pump (a) to the pipeline mixer (c);

•The precipitant is placed in the precipitation preparation tank (b), stirred with water, dissolved, and sent by a small pump through a small yellow tube to a pipe mixer (c) mixed with water;

•The mixed water enters the corrugated plate area (d), and the water turbulently pulsates between the corrugated plates and moves upwards, so that the soil impurities in the water are thoroughly mixed with the precipitating agent, and are adsorbed by the precipitating agent into flocculent mud clusters, when the water level reaches the height of the baffle plate A part of the water flows into the mud collecting area (e) until the water level rises to be flush with the water level of the corrugated board area (d), and the water levels of (e) and (d) rise together into the left branch area (under the light blue area and the deflector the area between the tops), the water slowly rises slightly to the left in the thin inclined tube, and calms down, no longer turbulent;

•The mixed water continues to rise slightly to the left to the light blue area. There is nothing in this area. The mixed water has a tendency to move to the left, but when it continues to rise into the right inclined tube area ( dark blue area) (f), due to a sudden change in direction ( from The left rises to the right rise ) , and the heavier flocculent mud in the water is turned to the left to enter the mud collection area (e). Due to its heavier weight, it slowly sinks below the mud collection area (e);

•The lighter flocculent muds ascend into the right inclined pipe zone (f), where they adsorb into each other into a large flocculent mass, and settle down to the mud collecting zone (e);

•When the mud collection area (e) has more mud, start the mud pump to drain the mud (the mud pump is on the left side of the mud collection area) (e).

•After precipitation, the semi-clear water continues to rise into the buffer zone (g) , from the U -shaped collection tube (h) into the upper zone of the filter (i), filtered through the filter layer (j) to the bottom, and then from the water conduit ( blue tube) (k) rise into the clear water area ( white area ) above the filter, and drain down the clean water pipe (l) to the disinfectant mixer (n);

•The disinfectant is prepared in a disinfectant preparation tank. The disinfectant liquid is mixed into the disinfectant mixer (n) through the pipeline and mixed with clean water. After mixing, it is made into tap water, collected by the tap water collection tank (o), and then transport the water to where it was needed.

•When the filter pool is to be cleaned, open the valve below the vertical tube on the right side of the filter tank. Due to the action of the siphon, the clean water in the clear water area ( white area ) above the filter is flushed from the bottom to the top through the water conduit ( blue tube) (k). The filter layer (j), the flushed sewage is discharged from the vertical pipe on the right side of the filter tank to achieve inverse flushing.

•Backwashing is also possible for the inclined tube section and the mud collection area.

Of course, in good weather, for some clear and transparent water, the precipitant can’t be used; when it is heavy rain, the water will become turbid, and it is necessary to add some precipitant.

Inclined tube top view of drinking tap water automatic treatment and purification

Oblique tube structure diagram of drinking tap water automatic treatment and purification

Oblique tube structure diagram of drinking tap water automatic treatment and purification

Characteristics of Automatic Treatment and Purification Method for Drinking Tap Water

• The whole water treatment process is automatically completed by the equipment, include mixing, flocculation, sedimentation, mud collection, sludge discharge, water collection, disinfection, filtration, backwashing, sewage discharge, etc., and is easy to operate. It is a highly automated raw water treatment system.

• The turbidity of raw water is less than 3000mg/L , and after filtration, the turbidity of water can be kept below 3 mg/L.

• Precipitation with inclined tube, the effect is good.

• The application of siphon automatic backwashing technology eliminates the need for additional electrical equipment such as backwash pumps or air compressors.

• The quick sludge concentrating chamber and the adjustable automatic sludge discharging system can ensure the elimination of excess sludge impurities in time, thus ensuring the stable impurity particle removal rate.

• It has a small installation area and is easy to expand, renovate, and is easy to relocate or reuse.

----------------------------------------

Related Products

If you need other types of products, please click on the blue font below, you can browse another page to see the related introduction.

1. River and Lake Drinking Water Purification Treatment Equipment: Can treat raw water of rivers and lakes into drinking water, is ideal drinking water purification treatment equipment for a water plant.

2. Well and Mountain Water Purification Treatment Equipment for Drinking: The water purification treatment equipment can treat raw water of well and mountain into drinking water, have no RO equipment, automatic backwashing, and large processing capacity.

3. Drinking Water Revers Osmosis (RO) Purification Treatment Equipment: Can be used in the production of beverages, purified water and other food.

4. Ship's RO Desalination Treatment Equipment for Drinking Water: Use revers osmosis (RO) purification treatment methods to remove salt and other impurities in seawater, turning seawater into drinking water.

5. RO Desalination Treatment Equipment for Drinking Water on Land: Use revers osmosis (RO) purification treatment methods to remove salt and other impurities in seawater, turning seawater into drinking water.

6. Mobile Drinking Water RO Purification Treatment Equipment at Container: Is to install purification equipment into the mobile container, and after arrives at the scene, it can carry out purification of drinking water.

7. Laboratory Water RO Purification Treatment Equipment: Have more stringent filtration and revers osmosis (RO) equipment, can meet the laboratory's high-purity water requirements.

8. Treatment Equipment of Electric Heating Water Distillers for laboratory: Use electric heating the tap water to form vapor, and then condenses into pure distilled water.

9. OL-1305 Online Multi-parameter Water Analyzer Meter: Can continuously and accurately detect water conductivity, pH, or dissolved oxygen concentration.

10. Portable Multi-Parameter Water Meter Tester: Is mainly used to measure pH, ORP (oxidation-reduction potential), TDS (total dissolved solids), salinity or conductivity in water or solution.

----------------------------------------