Anti-corrosion 2-piece Can Body Making Machines Line

Item No.: MTP-2G-2003

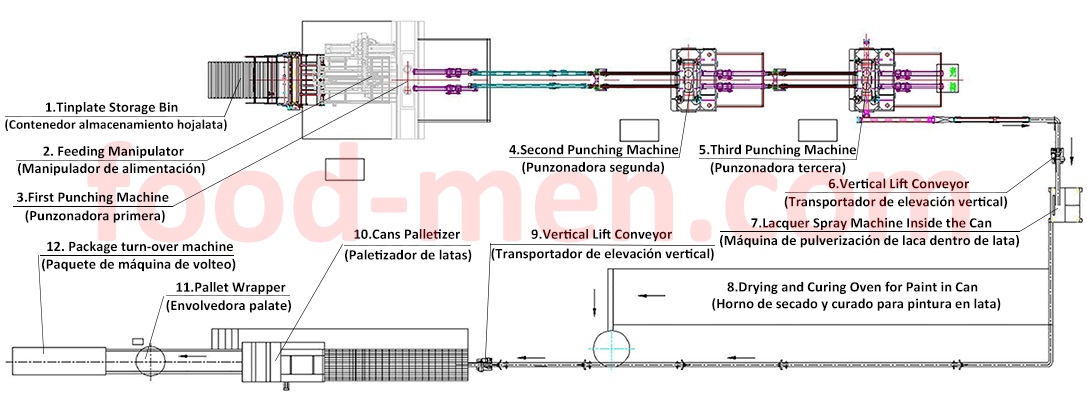

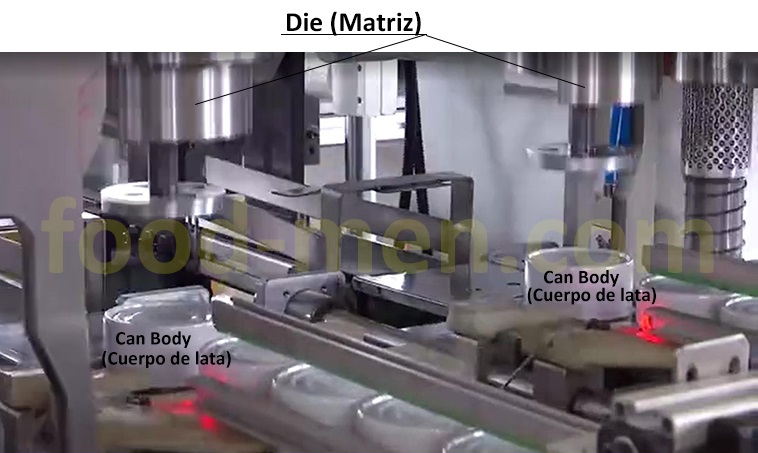

This anti-corrosion 2-piece can body making machines line uses multiple stamping (DRD) technology to make food can, is automatic machinery.

| Product parameters |

| Product Name: |

Anti-corrosion 2-piece Can Body Making Machines Line |

| Model Number: |

TP-2G |

| Brand: |

L.W. |

| Minimum Order Quantity: |

Part of the anti-corrosion 2-piece can body making machines line can be ordered. |

| Price: |

The price is determined according to the parameters and quantity of the order. |

| Supply Ability: |

1 anti-corrosion 2-piece can body making machines line per month |

| Place of Origin: |

China |

INQUIRY